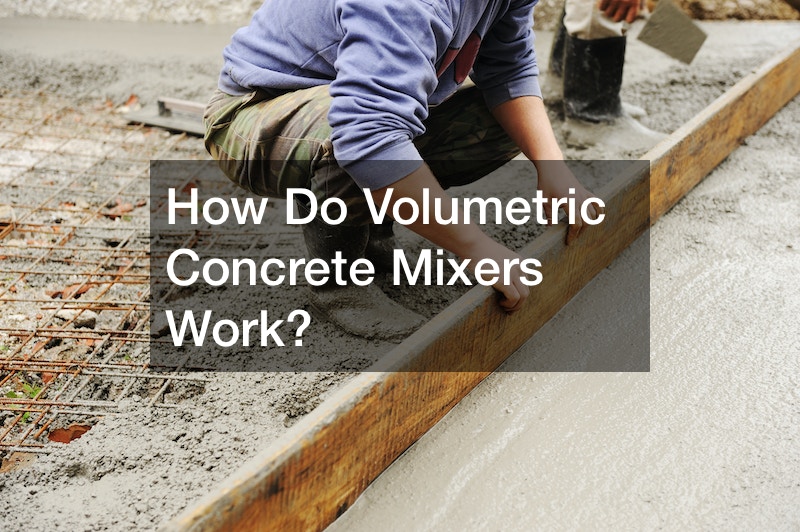

Concrete mixers are inexpensive to manufacture. Mixers are well-understood machines that are easy to fix. They work with large loads of material. Concrete mixers handle most jobs well. But they can be wasteful of material.

Once the cement is wet, builders must use it quickly. Customers are charged for the entire load by the concrete supplier, whether they use it or not.

Volumetric Mixers

Harold Zimmerman invented a mixer that held sand, stone, cement, and water separately and mixed them in discrete quantities on-site. This has major advantages for your workforce. The powder stays dry until it’s needed. There’s no anxious waiting in traffic with a load of concrete spinning and curing in the back.

Volumetric Mixers are Proven Technology

Zimmerman patented the first volumetric mixer in 1965. They are an energy-efficient alternative to drum mixers. Volumetric mixers can pour different types of concrete with the same materials. The user programs the computer with the volumetric concrete delivery mix as needed.

Volumetric mixers are also cheaper for the customer. Since the concrete ingredients stay separate until mixed on-site, the customer is only charged for the amount poured.

We hope you found this article informative about volumetric concrete mixers and their use in construction.

.